Lead Bullets, Lead Alloy bullets and Bullet Rounds

Bullet Metal Alloys, Ammunition metal

Pure virgin alloys for lead bullets in stock:

- Pure virgin alloys stock

- Hardball alloy – 2% tin / 6% antimony / 92% lead

- 2% tin / 7% antimony / 91% lead

- 10-1 alloy – 91% lead / 9% tin

- 16-1 alloy – 94% lead / 6% tin

- 20-1 alloy – 95% lead / 5% tin

- 30-1 alloy – 97% lead / 3% tin

- 40-1 alloy – 97.5% lead / 2.5% tin

- 50-1 alloy – 98% lead / 2% tin

- Linotype – 3% tin / 11% antimony / 86% lead

- Lyman #2 – 5% tin / 5% antimony / 90% lead

- Hard alloy – 3% antimony / 97% lead

- Hard alloy – 6% antimony / 94% lead

- Alloy: 0.5%Sn / 6%Sb / 93.5%Pb

- Alloy: 1%Sn / 3%Sb / 96%Pb

- Alloy: 2%Sn / 7%Sb / 91%P

- MIL-L-13283C Grade 1

- MIL-L-13283C Grade 2

- MIL-L-13283C Grade 3

- Musket Lead and Round Ball – 100% Pb

Nuclead will custom alloy lead for your individual lead bullet needs, per your specifications.

Fabrication of Lead Bullets

Nuclead will fabricate the mold and cast your lead bullets, or CNC turn them for precision results up to 0.0001″ and exact weight.

Mold Fabrication, Castings and Pours

We machine molds specified by your blueprint or CAD/CAM file, then pour them with your choice of lead or alloy. We can also machine, finish, plate or paint the product, QC it and deliver it direct to your dock. We have standard continuous pouring capability up to 40,000 lbs. (100,000 lbs. for special requests). We pour void free-lead as required.

CNC & 3D Machining

Sharp Manufacturing can program and machine all your lead and metal needs to within .000050″. Our Quality Control department has CMM capabilities to QC your products accurately, with all equipment calibrated to NIST standards. Our programming department has the latest CAD-CAM Auto Assist software available today. Solid models can be e-mailed and posted for complex 3D machining.

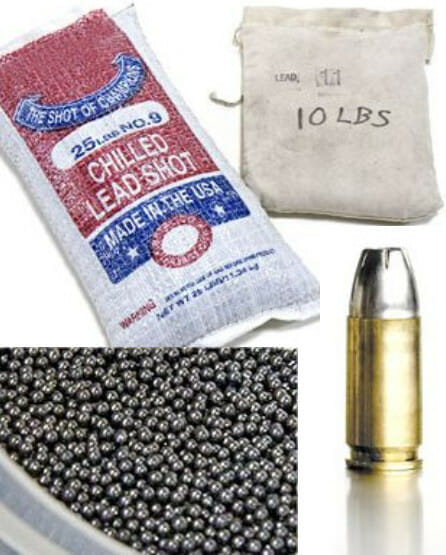

Lead Shot, Lead Bullet Alloys

Shot Types

Lead Shot, Ammunition Metal, Leadshot

(10-25 lb. bags, special orders to 40,000 lbs.)

Chilled:

#12 (.050″), #11 (.060″), #10 (.070″), #9 (.080″), #8 (.090″), #7.5 (.095″), #6 (.110″), #4 (.130″),

Magnum:

#9 (.080″), #8.5 (.085″), #8 (.090″), #7.5 (.095″), #7 (.100″), #6 (.110″)

Steel shot

(5-10 lb. bags, size in diameter)

#7 (.100″), #6 (.110″), #4 (.130″), #3 (.140″), #2 (.150″), #1 (.160″) #BB (.180″), #BBB (.190″), #T (.210″)

Hevi shot

(7 lb. bags)

#00 Buck, #B, #5, #9, #75, #6, #4, #2

Nickel plated lead shot

(11 lb. bags, size in diameter)

#9 (.083″), #8 (.091″), #7.5 (.095″), #7 (.100″), #6 .110″), #5.5 (.115″), #5 (.120″), #4 (.127″), #3 (.140″), #2 (.150″), #1 (.160″), #BB (.180″)

Buckshot, lead balls

(8 lb. bags, size in diameter)

#B (.170″), #BB (.180″), #BBB (.190″), #T (.200″), #F (.220″), #4 (.240″), #2 (.270″), #1 (.300″), #00 (.330″), #000 (.360″)

Bullet Metal Alloys

- Pure virgin alloys stock

- Hardball alloy – 2% tin / 6% antimony / 92% lead

- 2% tin / 7% antimony / 91% lead

- 10-1 alloy – 91% lead / 9% tin

- 16-1 alloy – 94% lead / 6% tin

- 20-1 alloy – 95% lead / 5% tin

- 30-1 alloy – 97% lead / 3% tin

- 40-1 alloy – 97.5% lead / 2.5% tin

- 50-1 alloy – 98% lead / 2% tin

- Linotype – 3% tin / 11% antimony / 86% lead

- Lyman #2 – 5% tin / 5% antimony / 90% lead

- Hard alloy – 3% antimony / 97% lead

- Hard alloy – 6% antimony / 94% lead

- Alloy: 0.5%Sn / 6%Sb / 93.5%Pb

- Alloy: 1%Sn / 3%Sb / 96%Pb

- Alloy: 2%Sn / 7%Sb / 91%P

- MIL-L-13283C Grade 1

- MIL-L-13283C Grade 2

- MIL-L-13283C Grade 3

- Musket Lead – 100% Pb

Nuclead can also custom alloy lead bullets for our customers’ individual bullet lead needs, or fabricate bullets to .0001″.

For more information on Lead shot applications and Lead Shot history Please click for lead shot applications information.

Please click for lead alloy pours applications information.

Other Customized Lead Products:

- Lead Sheet/Plate/Foil

- Lead Shielding

- Lead Bricks/Blocks/Interlocking

- Lead Weights/Ingots

- Lead Racing Weights

- Nuclear Casks/Containers

- Other Custom Lead Items Fabricated to Spec

- Lead Fishing Sinkers/Weights

Custom Lead Precision Services:

- Lead 3D Machining & General CNC Machining

- Lead Welding

- Lead Assembly – Lamination, PSA/Adhesives & Stamping, Sawing & Cutting

- Lead Alloy Pours & Mold Fabrication

- Gamma Inspection

- Quality Control

Call our offices today for more information on our custom services.

For a complete listing of products available on this site, go to theproducts and services index page

Visit our quotes and orders page for a custom quote.